It’s everyone’s favourite celebratory tipple, but just how is Champagne made? You might think that in these modern times the Champagne production process would be a fully industrial and automated one. In truth, the way Champagne is made has changed very little since the 17th-century days of Dom Perignon himself.

The traditional, time-consuming, and highly regulated process is what gives Champagne its delicate texture and delightfully fruity flavours. Exciting to learn more? Let’s take a look at the step-by-step process and find out what makes our favourite sparkling drink so unique.

Table of contents:

The Champagne production process step by step

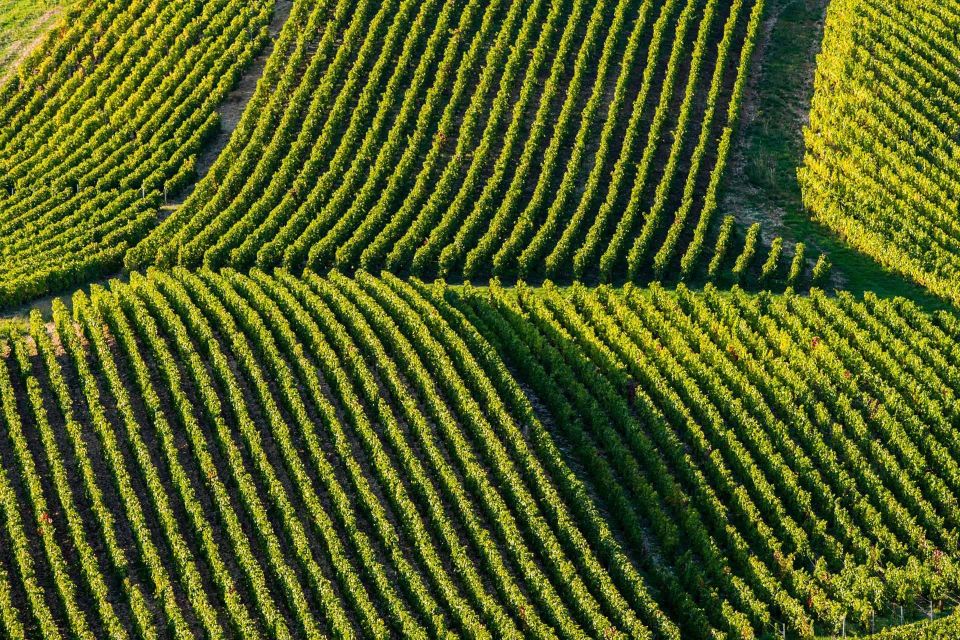

Champagne wine can only be made in the northeast Champagne region of France, where there are very particular climate and soil conditions.

The Champagne production method is known as the méthode traditionelle or méthode champenoise. It's a time-consuming, complex and highly regulated process that follows traditional methods and typically takes between 15 months and 3 years depending on the wine.

1. Hand-picking the grapes

Champagne grapes are harvested sometime around August to October each year. Exactly when depends on when the grapes reach optimum ripeness. The grapes used for Champagne must be grown in the Champagne region of France, otherwise, it's not Champagne, it's simply sparkling wine. The grapes are hand-picked to make sure that only the best quality, ripened grapes are used for the wine and that the skins remain intact before crushing.

There are three main grape varieties used in Champagne: black grape varieties, pinot noir and pinot meunier and white chardonnay grapes. Although not as common in Champagne production, pinot blanc, pinot gris, petit meslier and arbane grapes can all be used to make the wine too.

2. Crushing the grapes

The hand-picked grapes are collected and then quickly and gently pressed, either in traditional coquard baskets or pneumatic presses. A standard press will squeeze the juice from around 4,000kg of grapes at one time.

The clear juice produced at the start of the press, or cuvée, is separated from the darker, more “impure” juice towards the end of the press.

Any remaining impurities from the cuvée are removed by a process of settling known as débourbage that encourages solid particles to sink to the bottom while clear juice is siphoned off the top.

3. Primary fermentation

Following the débourbage filtration process, the clear grape juice goes through its first fermentation process. The grape juice is typically placed in a stainless-steel tank, although some Champagne makers prefer to ferment wine wholly or partially in oak casks. Using a wooden cask is a more difficult and expensive process, yet can produce a deeper flavour profile. All of the natural sugars present in the grape juice are fermented out of the wine until it is completely dry.

4. Assemblage or blending

Following primary fermentation, about 5 months after the initial harvest, assemblage begins. This is where the critical art of blending happens, an important step in keeping the style and flavour of a Champagne consistent year after year.

Some well-known Champagne blends include:

- Taittinger's non-vintage brut reserve: a dry and refreshing blend of 40% Chardonnay, 35% Pinot noir and 25% Pinot Meunier.

- Bollinger's special cuvee: a deep and subtle blend of 60% pinot noir, 25% Chardonnay and 15% Pinot Meunier.

- Dom Perignon only releases vintage Champagne, meaning each wine is uniquely grown from the best grapes of the season. Each vintage changes but the blend is typically around 50% pinot noir and 50% Chardonnay.

- Pol Roger's rose 2015 vintage: a fresh and fruity blend of 60% pinot noir and 40% Chardonnay, topped up with 15% still red pinot noir wine.

- Laurent Perrier's la cuvee non-vintage: a light and citrusy blend of 50% chardonnay, 35% pinot noir and 15% pinot meunier.

Wines from different grape varieties, vintages and vineyards are combined to also obtain different styles of Champagne.

- Blanc de Blancs: a “white from white” Champagne, lighter in style and made from white chardonnay grapes.

- Blanc de Noir: a “white from black” Champagne made from black pinot noir or pinot meunier grapes.

How is Rosé made?

- Rosé Champagne production consists mainly of blending red and white wines together, however, there are two methods of making rosé champagne or pink champagne as it is also known; the first is 'rosé d'assemblage' or blended Champagne which is by blending red and white grapes together and the second is 'rosé de saignée' or macerated Champagne which is when the pinkish colour comes from the crushed grape skins.

5. Second fermentation

Following assemblage, the second fermentation takes place. This is the most important step in the Champagne production process. A mixture of cane sugar and yeast, known as the liqueur de triage is added to the wine and the mixture is decanted into thick long-necked glass bottles and placed in a cool cellar.

The secondary fermentation occurs slowly over a 1-3-week period, resulting in alcohol and carbon dioxide being produced inside the bottle. The carbon dioxide dissolves in the wine, creating the signature Champagne bubbles.

6. Ageing

After fermentation, the wine is aged in the cool cellar for a minimum of 15 months for non-vintage wine and 3 years for vintage. The dead yeast cells split open as the wine ages, giving Champagne its typical toasty, yeasty character.

7. Riddling or remuage

Following the ageing process, the dead yeast cells and leftover sediment are removed in a process known as riddling. The bottles are laid sideways at a 75-degree angle and rotated 1/8th periodically. This process loosens the left-over yeast cells and moves them towards the bottleneck, ready for disgorging.

8. Disgorging

The final step in the Champagne production method is known as disgorgement. The bottle is kept at a 75-degree angle and the yeast residue that settles in the bottleneck is removed through a process of flash freezing. Once the residue is frozen solid, the bottle cap is removed, and the carbon dioxide pops the frozen residue out of the bottle, leaving only the clear Champagne behind.

9. Dosage

Following disgorgement, a little bit of wine is lost and the bottle has to be topped up. A small mixture of white wine, brandy and sugar, known as the Liqueur d’Expedition, is added to the Champagne. The dosage determines the Champagne’s sweetness and whether it becomes brut nature (or zero dosage), extra brut, brut, extra sec, sec, demi-sec or doux Champagne.

10. Corking

Finally, the Champagne is corked and sealed for protection with a wire cage known as the muselet. When the cork is inserted, it is cylindrical in shape, but as a result of compression, develops its classic mushroom shape over time.

Once the bottle is corked, it’s then rested for an additional few months before it's ready to be released on the market. This may be extended depending on the type of Champagne and what style and quality the brand is trying to achieve.

So, to summarise...

The complex and specialised production method makes producing Champagne a time-consuming and expensive process. Hand-picking grapes, double fermentation, expert blending and riddling all take time and patience. But, these steps all make Champagne a truly unique and exquisite drink that’s definitely worth waiting for.

For more information take a look at our Champagne guide.